3D Printing Role in Oral and Maxillofacial Surgery Current and Future Trend- Juniper Publishers

JUNIPER PUBLISHERS-OPEN ACCESS JOURNAL OF DENTISTRY & ORAL HEALTH

Abstract

The application of three-dimensional (3D)

printing enables virtual simulation surgery with tremendous details.

Data is usually obtained from detailed computed tomography (CT) scan and

the creation of material objects from digital images by depositing

layers into 3D structures. That can be used for training, education,

surgical planning and prosthetic reconstruction. We report on two

patients with complex reconstructive option in maxillofacial surgery

where 3D technology was utilized to analyze the tumor size, location,

and extension more precisely which drastically aids in better

preoperative planning Another case was for fabrication of custom 3D pure

titanium TMJ joint for reconstruction with optimal fit and function.

Keywords: 3D Printing;

Personalized medicine; Personalized surgery; Virtual surgery; Customized

prosthesis; Medical models; Custom TMJ; Titanium TMJ implant;

SclerodermaIntroduction

Medical applications for 3-D printing are expanding

rapidly and are expected to revolutionize health care. 3-D printing is

currently $700 million industry with only 11 million (1.6%) being

invested in medical applications. In the next 10 years it is expected

that 3-D printing will grow to $8.9 billion industry and 1.9 (26%)

billion is projected to be spend in medical applications.

Medical uses for 3-D printing can be categorized into three segments.

- Bioprinting tissue and organ;

- Creation of customized prosthetics, implantable devices and medical models

- Pharmaceutical drug dosage forms delivery and discovery.

Most reconstructive surgeons are familiar with

Charles Hull invention of 3-D printing “stereo lithography” in the early

1980’s. 3-D printing has since evolved and been applied in medicine

since the early 2000s. The first applications were used in dental

implants and custom prosthetic devices. Since then it’s applications

have significantly grown and most recent published reviews describe the

use of 3-D printing to produce bone, ears, trachea, blood vessels,

tissue organs as well as novel dosage form for pharmaceuticals by

personalizing drug printing fabrication at point of care while taking

into account patient age, gender, race and clinic response.

In this article we will focus on creation of

customize prosthesis, implantable devices and anatomical models within

the oral maxillofacial surgery practice [1].

Case 1 - Custom 3D pure titanium TMJ prosthesis

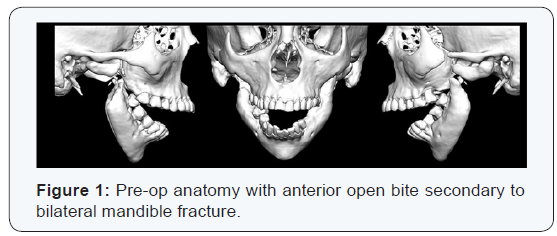

64 year old female with history of scleroderma has developed

a spontaneous pathologic fracture of her mandibular angle

bilaterally over 3 years ago. As a result, she developed significant

anterior open bite (Figure 1) with inability to chew food

requiring parental feeding for nutrition. She has seen multiple

surgeons within the US who have not been able to assist her

in her reconstructive needs due to the complexity and surgical

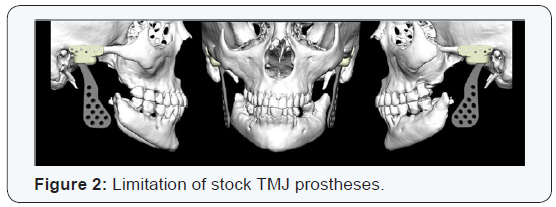

limitations. After CT evaluation and virtually ideal occlusion

alignment patient seem to have had significant bone resorption

bilaterally. Patient also does not have enough proximal condylar

head to allow any fixation. Additionally, a stock Total TMJ

prosthesis would not be able to reach the distal segment of the

mandible bilaterally after it is properly alignment (Figure 2). The

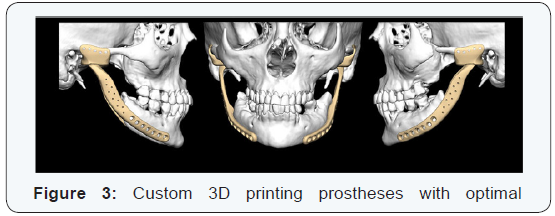

only option left is to create custom 3D temporomandibular joint

replacement pure titanium, as she exhibited sensitivity to nickel

(Figure 3). Currently Biomet custom joint are not FDA approved

in the United States however though the compassionate use

program we have been able to secure approval from the FDA

to custom make the implant to this the patient. Without the 3D

printing option for the custom prostheses this patient would

continue to suffer and live a life with significant compromised

quality of life [2].

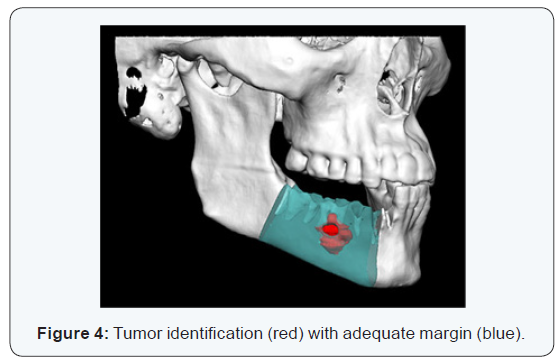

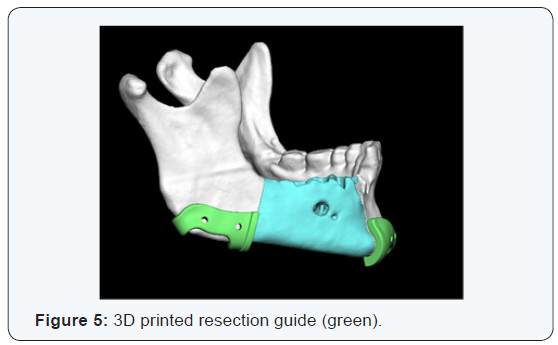

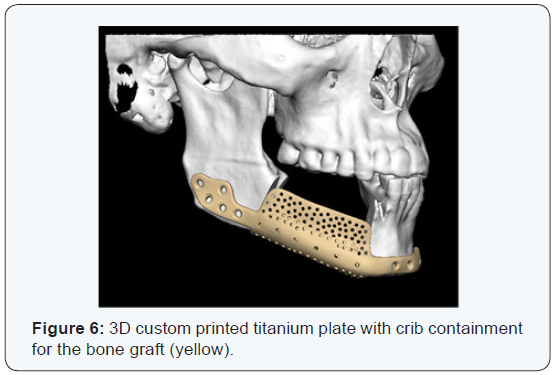

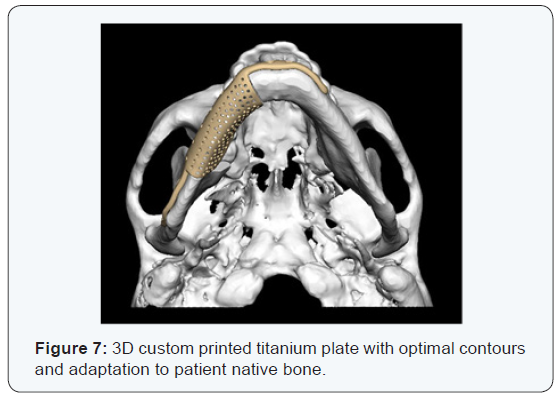

Case 2- Custom 3D Titanium Crib

34 year old male with destructive lesion in mandible that

was identified as a myxoma after biopsy of his right mandible.

Surgical plan was made to undergo partial mandibulectomy

with adequate margin. After conversation with the patient

we decided to reconstruct with custom 3D printing titanium

plate with crib containment. This allows for corticocancellous

bone graft from anterior iliac crest with bone marrow aspirate

concentrate (BMAC) and platelet rich plasma (PRP). BMAC is

a minimally invasive procedure used to collect bone marrow

from the patient’s own body (autologous) and concentrates it

to the optimal level while keeping all cell types, including adult

stem cells, mesenchymal cells and bone morphogenic protein

signal. While PRP acts are a stimulator for bone and soft tissue

healing via several growth factures enhancing bone maturity

and consolidation [3]. This 3D plate allows the patient to obtain

optimal cosmetic outcome as we are able mimic the pre-existing

contours, width and height of bone making dental implant

rehabilitation easier and more predictable (Figure 4-7).

Conclusion

Despite advances 3-D printing there are significant barriers

and controversies. Some of which are unrealistic expectation in

particularly regarding tissue/organ printed, safety and security

issues, and regulatory approvals. Regardless of the challenges

3-D printing is expected to play an important role in the trend

towards personalized medicine and revolutionize healthcare. It

is through the vision and collaborative support that allows us to

service these complex cases.

For more Open

Access Journals in Juniper

Publishers please click on: https://juniperpublishers.com

For

more articles in Open Access

Journal of Dentistry & Oral Health please click on:

Comments

Post a Comment