In vitro Comparison of Marginal Fit of Cad-Cam Zirconia, SMLS Co-Cr, Pressable Lithium Disilicate, and Cast Ni-Cr Copings - Juniper Publishers

JUNIPER

PUBLISHERS-OPEN ACCESS JOURNAL OF DENTISTRY & ORAL HEALTH

In vitro Comparison of Marginal Fit of Cad-Cam Zirconia, SMLS Co-Cr,

Pressable Lithium Disilicate, and Cast Ni-Cr Copings

Authored by Jitendra J Mete

Abstract

Context:Clinically acceptable

marginal fit of crowns has been the focus of various investigations.

There is limited literature comparing marginal accuracy CAD-CAM

zirconia, SMLS Co-Cr, Pressable Lithium Disilicate, and cast Ni-Cr

copings.

Aim:Evaluate and compare marginal accuracy of CAD-CAM zirconia, SMLS Co-Cr, Pressable lithium Disilicate, and cast Ni-Cr copings.

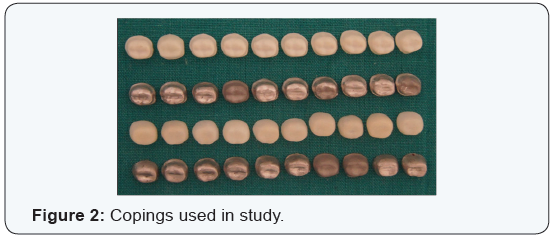

Methods and Material: Forty

copings were fabricated (Ten each in Group I - CAD- CAM zirconia, Group

II - SMLS Co-Cr, Group III - lithium disilicate, and Group IV- cast

Ni-Cr copings) on a standardized stainless steel model with long chamfer

finish line. Four areas around the tooth surface namely mesial (M),

distal (D), buccal (B) and lingual (L) surfaces were digitally analyzed

for marginal fit under the stereomicroscope.

Stastical Analysis: Comparison between groups was done by using one-way ANOVA test followed by a Post Hoc Tukey-Kramer multiple comparisons test.

Results: The mean marginal gap

(in μm) for Group I on lingual, buccal, mesial and distal surface was

37.05, 38.54, 37.61 and 36.09 respectively. The mean marginal gap (in

μm) of Group II on lingual, buccal, mesial and distal surface was 48.48,

50.88, 50.12, and 49.5 respectively. The mean marginal gap (in μm) of

Group III on lingual, buccal, mesial and distal surface was 63.04,

64.07, 64.97 and 65.81 respectively. The mean marginal gap (in μm) of

Group IV on lingual, buccal, mesial and distal surface was 75.68, 74.75,

73.86, and 72.78 respectively.

Conclusion: The marginal fit of

CAD-CAM zirconia copings is more accurate as compared to SMLS Co-Cr,

pressable lithium disilicate and cast Ni-Cr alloy copings on a

standardized metal model.

Keywords: Marginal Gap; Stereomicroscope; CAD – CAM; Metal Laser Sintering; Pressable CeramicAbbreviations: SMLS: Selective Metal Laser Sintering; Co-Cr: Cobalt-Chromium Alloy; CAD: Computer Aided Designing; CAM: Computer Aided Manufacturing; CNC: Computer Numerically Controlled (CNC); HIP: Hot Isostatic Pressing.

Introduction

The success of a dental restoration is determined by 3

main factors: esthetic value, resistance to fracture, and marginal

adaptation [1-5]. Inadequate marginal fit leads to cement dissolution,

plaque accumulation, which increases the risk of carious lesions &

periodontal diseases [6-11].

Traditionally metal copings have been fabricated by

the lost wax technique and casting method. Inaccurate marginal fit of

copings fabricated by this technique may result from contraction of

impression material, distortion of wax patterns, or irregularities in

the cast metal. Newly developed selective metal laser sintering (SMLS)

technique uses a high power laser to fuse the small particles of metal

into a mass that has a desired 3-dimensional shape. The laser

selectively fuses powdered material by scanning cross-sections generated

from the 3-dimensional digital description of the part (for example,

from a CAD file or scan data) on the surface of the powder bed. SMLS is a

CAD/CAM based technique in which frameworks and metal copings can be

designed and fabricated using cobalt-chromium alloy (Co-Cr). Co-Cr

powdered alloy used in this technique has slight variations in

composition. The molybdenum content in the alloy powder used in SMLS is

comparatively less than the alloy which is used for conventional

casting. After each cross section is scanned, the powder bed is lowered

by one-layer thickness and a new layer of material is applied on top.

The process is repeated until the part is completed. Advantage of SMLS

system include easy fabrication of complicated shapes and short working

time due to elimination of the procedures of fabricating a wax pattern,

investing, burning and casting works [12].

Development in ceramic materials such as lithium disilicate,

and zirconium oxide cores, uses of hot press and CAD-CAM

equipment have opened up new path for all ceramic restorations

[13]. CAD-CAM not only provides reproducible results fulfilling

certain standards but also reduces the errors arising from the

technicians. However, it is associated with higher cost. When

measuring the marginal gap after cementation, the same number

of teeth or steel dies as that of restoration sample is needed to

control the variables. On the other hand, only one tooth or steel

die is needed if the measurement is done without a luting agent.

Investigators have found a significant increase in the marginal

discrepancy after cementation [14,15]. These results, however,

varied according to the luting agent. The marginal fit was,

therefore, measured without cementation for variable control in

this study.

There is limited literature which compares marginal accuracy

of CAD-CAM zirconia, SMLS Co-Cr, Pressable lithium disilicate, and

cast Ni-Cr copings. So the present in vitro study was conducted to

evaluate and compare the marginal accuracy of CAD-CAM zirconia,

SMLS Co-Cr, Pressable lithium disilicate, and cast Ni-Cr copings.

Methods and Material

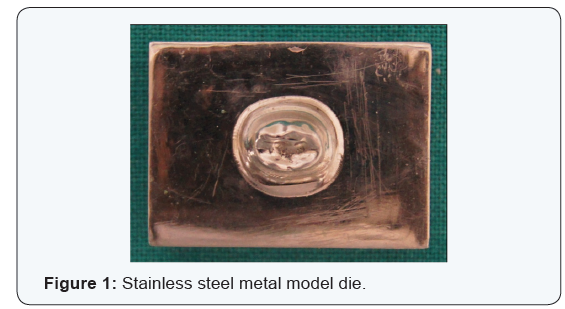

Fabrication of stainless steel master model

For fabricating a standardized master model, a typhodont

mandibular first molar tooth was first scanned using threedimensional

(3-D) computer-aided designing (CAD) software. After

scanning of the mandibular first molar tooth, a uniform chamfer

finish line of 1.2 mm in width, 6-degrees occlusal convergence, 1.5

mm reduction on functional cusps with functional cusp bevel and

1 mm reduction on non-functional cusps simulating a prepared

mandibular first molar was carried out on the CAD software. A

rectangular platform measuring 4 cm in length, 3 cm in breadth

and base of thickness 2 cm made of stainless steel material was

chosen for the purpose of milling. To fabricate a standardized

master model consisting of a metal die exactly in the centre of the

rectangular platform, computer-aided manufacturing (CAM) was

carried out using the data obtained from the CAD software which

was then transferred to the computer numerically controlled

(CNC) milling machine (LAVA CNC 500) and engraving was done.

After engraving, finishing and polishing of the master model was

carried out. The stainless steel metal master model was used to

fabricate all the copings and also to serve as an abutment for the

measurement of marginal discrepancy.

Fabrication of CAD-CAM zirconia copings

A dental CAD/CAM system, 3M LAVA CAD/CAM system (3M

ESPE Dental Products St. Paul, MN U.S.A) was used to fabricate

the 10 zirconia copings used in this study. Metal model of the

abutment was scanned using 3M Scanner. Scanned data were then

converted into CAD data. Copings for all-ceramic crowns were

designed using the dental wings supported by 3M software. No

cement space was included for the margin, and 45 μm was used for

the axial and occlusal surfaces of the abutment. Thickness of the copings were designed to be 0.5 mm. Design data were converted

into processing data and sent to the processing machine (CNC 500

LAVA 3M).The zirconia blocks were cut and milled, and then the

milled blocks were finally sintered to make zirconia copings. The

internal surfaces & margins of the copings after placing on die

were examined using a binocular loupe (HEINE HR-C 2.5x, HEINE,

Herrsching, Germany) to check the complete seating.

Fabrication of Pressable lithium disilicate copings

Ten copings were fabricated from lithium disilicate glass

ceramics (IPS e.max Press, Ivoclar Vivadent AG) using a

combination of the lost-wax and heat-press techniques. Die

lubricant (Isocera, Bego, Germany) was applied to the metal die.

Wax patterns were fabricated on the dies using dip wax technique

to form wax copings. The patterns were contoured parallel to

the emergence profile and margins were manually sealed under

1.5×magnification.The thickness of the copings was confirmed

with a thickness gauge (POCO 2N; Kroeplin, Schluchtern, Germany)

to be 0.5mm. Finally, to re-adapt the margin, the pattern was

reflowed completely through the wax over a band approximately

1mm wide with a well heated instrument, PKT No.1. Wax was then

added to fill the depression, and when the pattern had cooled,

the marginal excess was carved and the margin was burnished.

Patterns were invested in phosphate bonded investment (IPS

Press VEST Speed, Ivoclar Vivadent AG). After wax elimination

glass ceramic ingots (HO 2, Ivoclar Vivadent AG) were plasticized

at 9300C and vacuum pressed (EP 500 press furnace, Ivoclar

Vivadent AG) into an investment mold. After a holding time

of 25 min the pressed crowns were divested, separated and

cleaned by applying 1% hydrofluoric acid (IPS e.max Press Invex

Liquid, Ivoclar Vivadent AG) for 10 min. Internal surfaces were

sandblasted with 100 μm aluminum oxide at 2 bar pressure. The

internal surfaces of the copings were examined using a binocular

loupe (HEINE HR-C 2.5x, HEINE, Herrsching, Germany) and any

visible metal nodules were removed with water cooled diamond

bur. To detect the invisible nodules or irregularities, the internal

surfaces of the copings was checked on the master dies using vinyl

poly-siloxane disclosing paste (Fit checker; GC Corporation). After

removing the copings from the die, the contact spot, marked bythe indicator on the inside of the copings was examined visually

using a binocular loupe (HEINE HR-C 2.5x, HEINE, Herrsching,

Germany), these marked spots were removed until no internal

binding was occurred and a uniform thickness of disclosing

paste achieved. Finally, the copings were fitted to metal die. All

copings were manufactured under supervision by the same dental

technician.

Fabrication of cast Ni-Cr alloy copings

For making nickel-chromium (Ni-Cr) alloy copings, wax

patterns were fabricated in similar way as for Pressable lithium

disilicate copings. The wax patterns were invested with a

phosphate-bonded investment (Bellabond Plus, Bego, Germany)

and cast with Ni-Cr (Bellasun, Bego, Germany) alloy using an

induction casting machine (LC Cast – 60, Confident equipments).

After casting, the ring was bench cooled to room temperature and

divested. The copings were sandblasted with 50-μm Al2O3 at 0.2-

MPa air pressure to remove the investment. The internal surfaces

of the copings were examined using a binocular loupe (HEINE HR-C

2.5x, HEINE, Herrsching, Germany) and any visible metal nodules

were removed with a tungsten carbide bur (No. H71EF; Brasseler

GmbH and Go KG). To detect the invisible nodules or irregularities,

the internal surfaces of the copings was checked on the master

dies using vinyl poly-siloxane disclosing paste (Fit checker; GC

Corporation). After removing the crown from the die, the contact

spot, marked by the indicator on the inside of the copings was

examined visually using a binocular loupe (HEINE HR-C 2.5x,

HEINE, Herrsching, Germany), these marked spots were removed

until no internal binding was occurred and a uniform thickness of

disclosing paste achieved. Finally, the restorations were fitted to

metal die. All copings were manufactured under supervision by

the same dental technician.

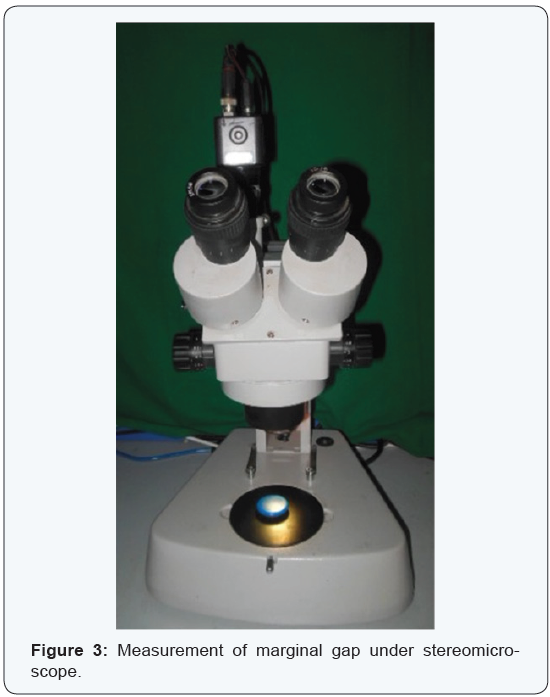

Every finished coping was placed on the prepared metal die

and checked for complete seating after which it is evaluated for

the marginal fit accuracy using a stereomicroscope (Wuzhou

New Found Instrument Co. Ltd., China, Model Xtl 3400 E). During

stereomicroscope evaluation copings were secured to master

die model using vice holder. Stereomicroscopic images were

analyzed using image analysis system (Chroma Systems Pvt. Ltd.

India) and measurements for marginal gap were taken on deepest

portion of copings on lingual, buccal, mesial and distal. Total

160 measurements were recorded of 40 copings, 10 of each four

study groups. The mean and standard deviation of marginal gap

of four Groups on lingual, buccal, mesial and distal surface was

calculated. Tukey-Kramer multiple comparison test was applied

for comparative evaluation of marginal fit in different groups.

Results

The mean ± SD marginal gap of Group I on lingual, buccal,

mesial and distal surface was 37.05 ± 4.19, 38.54 ± 3.68, 37.61 ±

4.05 and 36.09 ± 4.18 respectively. The mean ± SD marginal gap

of Group II on lingual, buccal, mesial and distal surface was 48.48

± 5.99, 50.88 ± 6.0, 50.12 ± 5.91 and 49.5 ± 5.67 respectively. The

mean ± SD marginal gap of Group III on lingual, buccal, mesial and

distal surface was 63.04 ± 4.21, 64.07 ± 4.26, 64.97 ± 4.41 and

65.81 ± 4.49 respectively. The mean ± SD marginal gap of Group

IV on lingual, buccal, mesial and distal surface was 75.68 ± 10.38,

74.75 ± 10.68, 73.86 ± 10.71 and 72.78 ± 10.61 respectively.

Tukey-Kramer multiple comparison tests was applied for

comparative evaluation of marginal fit in different groups. The

marginal fit of Group I on lingual, buccal, mesial, and distal

surfaces as compared to Group II, Group III and Group IV was

found to be statistically significant (p<0.001) (Table 1) & (Figures

1-3). The marginal fit of Group II on lingual, buccal, mesial, and

distal surfaces as compared to Group III and Group IV was found

to be statistically significant (p<0.001).The marginal fit of Group

III on lingual, buccal, and mesial surfaces as compared to Group IV

was found to be statistically significant (p<0.001).The marginal fit

of Group III on distal surface as compared to Group IV was found

to be statistically not significant (p>0.05).

Discussion

The ultimate goal of successful fixed partial denture (FPD)

prosthesis can be achieved only when an accurate and precise

marginal fit is produced. Microleakage and marginal openings are

important causes of fixed restoration failures. One of the reasons

for high microleakage is the amount of marginal gap, the increase

of which causes greater microleakage, because the amount of

cement exposed to oral fluids depend on the extent of the marginal

gap [16].

Marginal discrepancies in the range of 40-120 μm have been

reported to be clinically acceptable with regard to longevity

of a restoration [17]. All the copings tested in this study are in

the range of 35-80 μm, which is within acceptable limits. The

different materials and applied techniques in the manufacturing

of crown systems have significant effects on the strength of the

final restoration as well as the marginal fit. Imperfect restoration

margins offer recesses for adherence of oral bacteria, which may

cause secondary caries and traumatic gingival irritation [18]. This

in vitro study examined the marginal adaptation of four types of

copings, consisting of frameworks fabricated using CAD/CAM

zirconia, selective metal laser sintering (SMLS), pressable lithium

disilicate and cast nickel-chromium (Ni-Cr) alloy. The marginal

discrepancies of group CAD/CAM zirconia were significantly

smaller compared to those of the other three study groups.

A stainless steel die was used for making copings and served

as the abutment for the measurement of marginal discrepancy for

all the copings made in this study. The advantages of the stainless

steel die are standardized preparation and avoidance of wear of

the die during the coping fabrication and measurements. The deep

chamfer finish line preparation was selected because it meets

the requirements for all the four study groups used in this study

[19]. The majority of marginal discrepancy is known to develop

during the oxidation cycle for metal copings [20]. This is often attributed to the release of residual stresses incurred during

casting, grinding or polishing phases of the procedure. As the

prostheses cools from the firing temperature, the difference in

thermal contraction between the metal coping and the porcelain

may result in additional marginal discrepancy [21].

The mean marginal gap widths of the CAD/CAM zirconia

fabricated superstructures were significantly smaller than those of

the selective metal laser sintered frameworks. This finding can be

attributed to advancements in scanning technology, restorationdesigning

software with improved margin detection and precision

milling technologies. The vertical marginal gap values obtained

were within the range of clinical acceptance i.e. 40 μm to 120

μm. The CAD/CAM zirconia system mills the framework with the

final dimensions out of a densely sintered Y-TZP (Yittria stabilized

Tetragonal Zirconia Polycrystals) blank which is fabricated with

the ‘Hot Isostatic Pressing (HIP)’ technology. This technology

involves sintering partially sintered zirconia material at a high

temperature in a high density, homogenous zirconia material

with improved mechanical properties [22]. For CAD/CAM ceramic

crowns, marginal gaps of 17 μm to 118 μm have been reported by

various authors [23]. Similar results were obtained in the present

study.

However, a higher accuracy was achieved with the soft,

partially sintered Y-TZP ceramics compared with the hot isostatic

pressed (HIP) Y-TZP blocks. This finding can be attributed to the

ease of machining and the precisely controlled sintering cycle in

a specially designed sintering oven which aided in achieving a

consistently accurate fit. The lesser accuracy of hard HIP-YTZP

ceramics can be attributed to their extreme hardness and higher

flexural strength (> 1,200 MPa), which can cause greater wear of

the milling burs and a reduction in the efficiency of the milling

unit consequently leading to lesser accuracy of fit. The Post Hoc

comparison of both hard and soft types of ceramics showed no

statistical significance, indicating that either form of Y-TZP ceramic

produces clinically acceptable restorations. The comparable

mechanical properties and the relative ease and speed of soft

Y-TZP blank milling may explain why more operators choose this

method to fabricate zirconia restorations, whereas only a small

number prefer the hard Y-TZP blanks [24].

The results of the present study suggest that the new

zirconia

ceramic systems fabricated with CAD/CAM technology presents

better marginal fit as compared to selective metal laser sintered

copings. These results were in accordance with a study conducted

by Ece Tamac et al. [25]. The results of this study shows that

selective metal laser sintered copings shows better marginal fit

than pressable lithium disilicate and cast Ni-Cr alloy copings. This

finding can be attributed to the fact that additive manufacturing

is used during selective metal laser sintered copings fabrication

and this technique uses a high power laser to fuse small particles

of metal into a mass that has a desired 3-dimensional shape. The

laser selectively fuses powdered material by scanning crosssections

generated from a 3-dimensional digital description of

the part (for example from a CAD file or scan data) on the surface of a

powder bed. After each cross-section is scanned, the powder

bed is lowered by one-layer thickness, a new layer of material

is applied on top and the process is repeated until the part is

completed. These results are in accordance with Montero J. et

al who concluded that selective metal laser sintering may be an

alternative to vacuum-casting of base metals to obtain passivefitting

implant-supported crown copings [26].

Glass-ceramics have superior stability, biocompatibility,

esthetics, and chemical inertness, making them a viable

alternative restorative material. Leucite-reinforced glass-ceramics

were originally designed for CAD/CAM restorations because of

their high durability and ability to be milled accurately. These

ceramics are reinforced by the incorporation of leucite crystals

into their structure, giving them improved toughness and strength

[27]. In the present study, the leucite-reinforced glass-ceramic

superstructures showed higher accuracy of marginal fit compared

with the cast Ni-Cr superstructures.

IPS Empress Copings show less marginal gap than the

conventionally casted Ni-Cr alloy copings. IPS Empress 2 (Ivoclar

Vivadent, Schaan, Liechtenstein) is a lithium-disilicate glass

ceramic (SiO2-Li2O) that is fabricated through a combination of

the lost-wax and heat-pressed techniques. A glass-ceramic ingot

of the desired shade is plasticized at 920°C and pressed into an

investment mold under vacuum and pressure. Its predecessor,

IPS Empress (Ivoclar Vivadent) is a leucite-reinforced glass

ceramic (SiO2-Al2O3-K2O) which, due to its strength is limited in

use to single unit complete-coverage restorations in the anterior

segment. IPS Empress 2 has improved flexural strength by a

factor of 3 over IPS Empress, can be used for 3-unit fixed partial

dentures in the anterior area and can extend to the second

premolar. The framework is veneered with fluoroapatite-based

veneering porcelain (IPS Eris; Ivoclar Vivadent), resulting in a

semi translucent restoration with enhanced light transmission.

IPS e.max press (Ivoclar Vivadent) was introduced in 2005 as an

improved press-ceramic material compared to IPS Empress 2.

It also consists of a lithium-disilicate pressed glass ceramic, but

its physical properties and translucency are improved through

a different firing process [28]. Yeo IS et al. [29] concluded that

the IPS Empress 2 systems showed the smallest and most

homogeneous gap dimension, whereas the conventional In-Ceram

system presented the largest and more variable gap dimensions

compared with the metal ceramic restorations.

The conventionally casted Ni-Cr superstructures show more

marginal gap when compared with the CAD/CAM superstructures.

This finding can be attributed to the expansion and contraction

associated with the impression materials, gypsum, wax pattern

distortion during removal and the spruing process are other factors

that may affect the accuracy of superstructures fabricated using

the lost-wax process [30]. These results are in accordance with

a study conducted by Tamer E. Shokry et al. [31] who concluded

that titanium copings fabricated by CAD/CAM demonstrated the

least marginal discrepancy among all groups, while the base metal

(Ni-Cr) groups exhibited the most discrepancy of all groups tested.

It is difficult to interpret the statistical results of the previous

studies because of variations in sample size, the measurement

per specimen and the measurement methods used. There is

no standardized method to measure the marginal fit. The most

common methods are ‘direct viewing, sectioning, probing and

explorative and visual examinations’ [32]. In the current study,

the direct viewing of the crown on a die is used to measure the

marginal fit of all the copings. Direct viewing has the advantage of

being nondestructive and therefore applicable to clinical practice.

The vertical cervical marginal gap measurement was selected

as the most frequently used to quantify the accuracy of fit of a

restoration [33].

Conclusion

Within the limitations of the present study, following

conclusions can be drawn:

- The marginal fit of CAD/CAM zirconia copings is more accurate as compared to selective metal laser sintered (SMLS), pressable lithium disilicate and cast Ni-Cr alloy copings on a standardized metal master model.

- Base metal alloy (Ni-Cr) exhibited a discrepancy that was significantly higher than the rest of the groups.

- The marginal discrepancies of all the copings were within the clinically acceptable range of 80-120 μm.

For more Open Access Journals in Juniper Publishers please

click on: https://juniperpublishers.com

For more articles

in Open Access Journal of Dentistry & Oral Health please click on:

Comments

Post a Comment